Sara and carbon footprint assessment

Our employee blog shares updates directly from the heart of our operations: In this post, you’ll read about Sara’s experiences with carbon footprint calculation, which is a key element of our sustainability efforts. Sara works as a procurement engineer and is responsible for material procurement in the design phase, enabling a comprehensive understanding of the aspects considered in the calculations.

Working in a field where we make visible positive environmental impacts is rewarding, and continuous improvement is at the core of everything we do.

– Sara

Current state analysis

The carbon footprint calculation was carried out in collaboration with Third Rock last spring, focusing on the emissions for 2022. The collaboration was smooth, and assistance was readily available whenever needed. The calculation project progressed quickly to the results phase, taking approximately six weeks in total.

Before starting the calculation, the current situation was analyzed, and the major emission sources across the entire operation chain were identified. Typically, the largest emission source for companies is the sold products, and this was no exception, as their carbon footprint formed the most significant portion of the emissions.

At the beginning of the project, the calculation steps, scope, and timeline were reviewed. The process began with data collection, which was allocated about a month. Afterward, Third Rock calculated the carbon footprint, and the results were delivered within a few weeks. The calculation was conducted following the GHG protocol. After the first round of calculations, Owatec now has the capability to calculate the carbon footprint independently using the instructions and tools provided by Third Rock.

Data collection

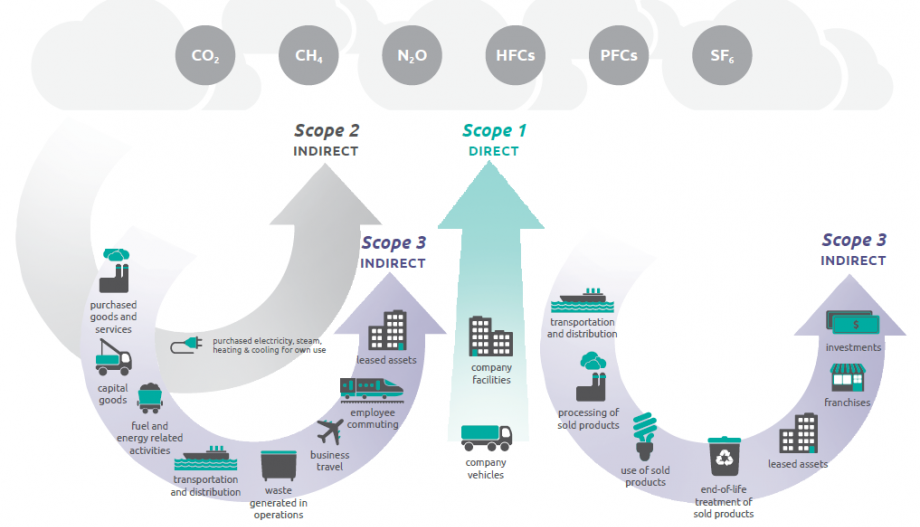

The data collection process began at our workplace with a four-person team. The calculation accounted for the most relevant aspects of Scopes 1, 2, and 3.

The first calculation was the most challenging, as data collection required a significant amount of time and effort to gather information from various sources. Not all companies we approached had already calculated their carbon footprint, but through excellent collaboration, we successfully collected the necessary data. Using conversion factors, we were able to calculate our carbon footprint for the first time. Some data was obtained directly as emissions figures or appropriate emission factors, while other data was derived on a cost basis.

For the 2023 carbon footprint calculations, we used the tool provided by Third Rock. The tool’s use was reviewed together with Third Rock, which gave us confidence in the accuracy of the calculations. The second round of calculations was noticeably easier since we knew where to find the data, how to process it, and what to consider for a thorough assessment.

Scope 1

Scope 2

Scope 3

This calculation takes into account indirect emissions, which include categories such as procurement and purchases, the lifecycle impact of energy production, inbound logistics, waste management, business travel, commuting, outbound logistics, and the use of sold products.

For Owatec, this category represents a significant portion of emissions, making one of our primary goals the establishment of sustainable supply chains.

Results and future goals

The carbon footprint has now been calculated twice, and for the first time in Owatec’s history, we can compare data between two different time periods.

This allows us to set clear development goals, and we have updated our internal guidelines to further reduce emissions.

Our goal is to ensure that all procurements are made from products manufactured either domestically or within Europe, which helps to minimize logistical needs. Transparency from our suppliers is also crucial, and selecting new suppliers becomes easier when their commitment to sustainability is clearly demonstrated.

Our own transparency is equally important to us. Starting in 2025, we will begin publishing annual sustainability reports.